Everything that’s hiding behind the lines painted on roads that you never imagined

25 of October of 2017

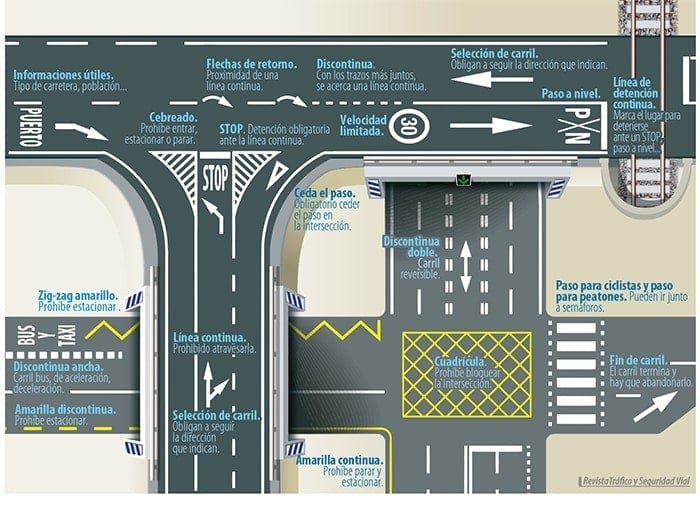

Continuous white lines, lines separating lanes and hard shoulders, marking no-go zones for traffic, zebra crossings… Road markings on the asphalt tell us many things that are allowed or not allowed, and they hide many secrets which you’ve probably never thought of.

What are the road marks painted on the asphalt?

A road marking, pursuant to the general Technical Conditions applicable to work on roads and bridges (Order FOM/2523/2014, of 12 December), is “a visual guide placed on the road surface, in the form of lines or signs, for the purpose of conveying information”.

As can be seen on the diagram, many of these markings are white, but some are yellow. Some may even be red (in red and white chequered markings), and matt black paint is also used (to cover up signs which are no longer in use). In many cases, the markings are reflective to improve visibility at night, and many are also skid-proof, to enhance the safety particularly of pedestrians and motorcyclists on rainy days.

How is all of this done? Francisco Javier Guerra Pineda, director of the AETEC laboratory, explains that road markings are prepared “with a basic material such as paint, which is spread on the road surface. The paint can have additives such as glass beads if looking for reflective properties; or aggregates such as sand, glass powder, etc. when skidding is to be avoided.”

For this reason, the paint or other basic material used in road markings must have the ability to “retain the glass beads and/or aggregate in order to conserve their reflective and/or anti-skid properties”.

What is road marking paint made of?

To achieve road markings with all of these properties (shine, retroreflection, durability, anti-skidding), the basic material and any additives (glass beads and anti-skid aggregates) must be combined in the correct proportions.  Depending on the materials and amount of each of these components used, different results will be obtained. In other words, “choosing the right materials and the correct amount of additives is all equally important,” says Guerra Pineda.

Depending on the materials and amount of each of these components used, different results will be obtained. In other words, “choosing the right materials and the correct amount of additives is all equally important,” says Guerra Pineda.

And how to get the proportions right? By following the instructions provided by the manufacturers, “once the amounts have been tested in the wear simulator”.

Not just any paint will do

Added to all this, the paint must be of a type capable of withstanding all types of vehicles, light and heavy, rolling over it, as well as resistant to “the liquids such vehicles may lose (some of them as corrosive as brake fluid), sunlight (UV rays), water, salt (from winter maintenance operations), ice, the sharp edges of snow ploughs, etc.” says Francisco Javier Guerra Pineda.

Because of this, only certain paints are up to such exacting standards. Solvent-based paints, water-based paints, cold plastics, thermoplastics and preformed tape are ideal for road markings, having been specially designed for this. Nevertheless, the director of the AETEC laboratory also clarifies that even amongst basic materials, “there are some which are better suited than others to withstand certain conditions”, and therefore “some are preferable to others depending on expected use”.

The materials aren’t my concern, your safety is

The highway code is, in general terms, the same in most countries. Is this the case also for road markings?

There are no specific requirements in Europe regarding composition of the basic materials (content as to binder, loads, titanium dioxide, etc.), contrary to in the US. Rather, there are requirements on performance of such materials in situ, explains the director.

Thus, “real conditions on the road are simulated and certain properties must be met to help keep roads safe. In other words, you could say that the European authorities are not worried about what ingredients make up the basic materials used, but more with the fact that they provide a minimum level of safety.”

And what performance characteristics make for safe roads? Visibility at night, visibility at night (in case of mist and after rain), visibility at night in rainy conditions, daytime visibility, daytime visibility for pedestrians, colour, and resistance to skidding in wet conditions.  In order to check that the markings fulfil all these requirements, there are two options or trial methods available: road trials (EN 1824) and wear simulator (EN 13197).

In order to check that the markings fulfil all these requirements, there are two options or trial methods available: road trials (EN 1824) and wear simulator (EN 13197).

What these two trials involve

According to Francisco Javier Guerra Pineda, the first of these involves “applying several lines across the carriageway using the marking system to be tested (base material plus beads), under the same conditions as would be encountered on the roads. Once dry, the road is opened to traffic and performance assessed after 1 year.” However, this option, he says, is not without its drawbacks. “Given that it is carried out in the open air, environmental conditions cannot be replicated.

In the event of an accidental spillage, the test would be cancelled”, and if a material fails, it cannot be submitted again until the following year. Moreover, the weight of vehicles (whether light or heavy) “cannot be controlled. And the most important drawback, and the reason why many countries do not use this test, is that all these lines painted on the road can distract drivers and potentially cause accidents.”

And that is why the wear simulator, a trial which lasts about a month, is usually the preferred option. To carry out these tests, the road markings are applied on a test surface “which simulates conditions on the asphalt exactly, both from a chemical and physical (roughness) perspective, and this test surface placed in a wear simulator”.

The AETEC director stresses the fact that in the simulator all the factors affecting wear can be controlled: measurements, design and composition of tyres, weight of vehicles, speed and temperature, which should always be between 5ºC and 10ºC. “Measurements are taken after a certain number of rollovers, i.e. the number of times that wheels roll over the road marking, with a maximum of 4,000,000 (P7, according to European Standard EN 13197)”, he adds.

A lick of paint is required…

In the so-called “operation asphalt” campaigns, we very often see that city streets and roads are resurfaced, or simply have their road markings repainted. How long does a coat of paint last on these markings? There is no one single, identical measure for this, as it depends on various factors, such as roughness of the surface (the same amount of paint will not cover a draining surface or a completely smooth surface to the same thickness); the amount of paint applied (the more paint, the longer it will last), and the type and location of the road (paint will not last for the same length of time on a central line on a narrow road, which all cars drive over, and on the left-hand [or right-hand in England!] line next to the central reservation which no one drives over).

“The degree of durability of a road marking is assigned to it based on the wear simulator test”, explains Francisco Javier Guerra Pineda, who goes on to add that there are several levels of durability in ascending order: P1, P2, P3… and up to P7 (4,000,000 million wheel roll-overs). “To reach these levels, all the minimum values for all the performance characteristics which define a safe road – as already mentioned previously – must be met after 4,000,000 wheel roll-overs.”

Thorough controls

To ensure that all road markings continue to meet all the necessary requirements, regular trials are carried out on some of these performance characteristics. “Depending on the scope of the work and the budget available (given that some of the actions required can be more expensive than a new lick of paint), specific characteristics are measured,” he says.  In general, visibility of all road markings at night is measured, since “very efficient equipment, capable of measuring at traffic speeds, is available. In other words, these devices can measure between 300 km to 500 km of road markings per day. If they do not meet the minimum requirements as specified in the Particular Conditions, or technical regulation PG-3, repainting will be necessary.”

In general, visibility of all road markings at night is measured, since “very efficient equipment, capable of measuring at traffic speeds, is available. In other words, these devices can measure between 300 km to 500 km of road markings per day. If they do not meet the minimum requirements as specified in the Particular Conditions, or technical regulation PG-3, repainting will be necessary.”

What happens if the road markings are worn? “In most cases, if they are within the warranty period provided by whoever applied them (the contractors using the basic material rather than the manufacturers), then such contractor must provide a solution, either by repainting (placing a new coat of basic material over the “old”), or by scraping off the old and applying new material on “clean” asphalt.

The concessionary company of the road is responsible for deciding which of these solutions to apply”, the AETEC laboratory director confirms. In other cases, however, the State and the concessionary company “set specific values for the performance characteristics, and use these to apply a fine or a bonus, or neither of the two. Which means that the concessionary company will strive to ensure that the performance of the road markings is always in the bonus area.”

There are no comments yet