Since I began my studies in civil engineering at the Technical University of Madrid, I always knew that I wanted to dedicate myself to maritime engineering. Though my roots go back to a dry land (Ciudad Real), courses on hydraulics were the ones that caught my attention the most, and from very early on, I steered my career in that direction.

After two international exchange programs where I specialized in maritime projects, I finished my bachelor’s degree in 2016. That year, I moved to the United Kingdom. There, I started working on the urban planning team for well-known design consultancy WSP. However, I soon realized that I had to continue to pursue my interest in marine infrastructures. In January 2018, I joined Ferrovial Construction.

Ever since, I’ve been part of the technical management team for the Thames Tideway Tunnel project in London, specifically the Maritime Construction team with Francisco Javier Quesada Colmenero.

Our role is coordinating and supervising various consulting firms to offer designs that are buildable and profitable and buildable. We work together to ensure that the technical solution is both faithful to projections and is finished within the given programme deadlines.

The Thames Tideway project

London’s sewer system was built in the 19th century for 4 million people. Today, with a population that has doubled, the system is obsolete. When it rains, wastewater saturates the system and flows into the river through spillways called the Combined Sewer Outfall (CSO).

The continual overflow and ever-growing population aggravate the problem, increasing the levels of pollution in the river.

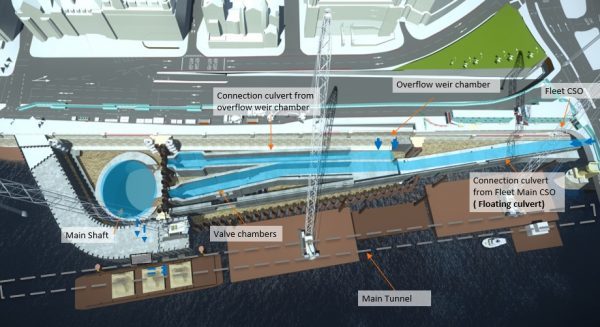

The Thames Tideway Tunnel (TTT) is one of the United Kingdom’s largest projects to date. The goal is to modernize the English capital’s combined sewer system by building a large underground collector. The collector runs 40 meters below the River Thames and will connect to existing spillways on the riverbank through permanent structures (pipes and wells).

Cofferdams

Ferrovial Construction and Laing O’Rourke form the joint venture that is constructing the scheme’s central section, located in the heart of London. This section consists of eight sites, each with their own identity; seven of them involve maritime construction.

To enable dry construction of the permanent works, cofferdams had to be used. Two main types were designed: double sheet pile walls and pile walls. One clear example of the complexity of this work is Blackfriars Bridge Foreshore (BLABF).

The BLABF cofferdam (see image below) is located 100 meters upstream from Blackfriars Bridge on the Waterloo and City subway line. It is supported by the riverbank wall, which was built 120 years ago in Victorian times.

Due to a very tight construction schedule, the temporary structure is divided into three zones (west, central, and east). This allows for parallel construction on the permanent structures. Different maritime typologies have been built based on each area.

West, central, and east zone

In the West Zone, there is a double cofferdam measuring 10 meters wide and 12 meters high on the riverbed. The walls are of the high-modulus variety made of H-piles 25 meters long and sheet piles 15 meters long.

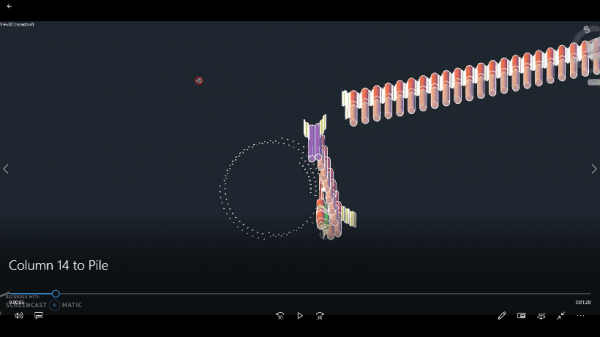

This area was the first to be built; It houses excavation on a secant pile shaft measuring 22 meters in diameter and more than 50 meters deep. Before drilling the well’s piles, jet grouting was performed to improve the terrain – one of the deepest treatments of this kind to date in the United Kingdom.

Due to spaciale constraints, a 3D model had to be used. Using BIM technology made it possible to monitor the position and gradient of the perforations, ensuring contact between columns and protecting existing structures.

Construction in the Central Zone has a combined cantilevered wall 12 meters high over the riverbed. The wall is built with hybrid piles (metallic and reinforced concrete) measuring 30 meters in total. In this area, two transverse walls have been built up against the existing riverbank wall. They create the temporary dry dock where the caisson-collector will be built.

The central area, measuring 2,500 m2, houses a dry dock with the work platform 9 meters below high tide. A floating caisson of reinforced concrete will be built there at 100 meters long, 7 meters wide, and 7 meters high. This caisson will act as a collector connecting the existing sewer system with the well in the west zone when it is anchored in its final position.

The East Zone consists of an open sea excavation for building the leveling pavement for the floating concrete caisson-collector.

All maritime structures have been carried out by marine means. By doing it this way, not only has the impact on Londoners’ lives been minimized: CO2 emissions have also been reduced. The cofferdam project has now completed succesfully.

Its completion has made it possible to carry out another project that Ferrovial is participating in on the Thames Tideway Tunnel: the construction, transportation, and placement of the floating culvert at Blackfriars. This floating pipeline will connect the city’s sewer system with the large underground collector that will run under the river.

There are no comments yet