The most straightforward and accurate definition of ‘waste recovery’ that I have heard came from my five-year-old daughter when I asked her if she knew what daddy did at work and she replied, “You take rubbish and turn it into money”.

Taking rubbish and turning it into money is also known as Circular Economy, where waste is no longer looked upon as remains and is transformed into a source of energy (energy recovery) or a raw material for the production process (material recovery).

By contrast, in the Linear Economy, in which we have consciously been living for 200 years or so, and unconsciously since the invention of the landfill, rubbish is simply regarded as remains with no attached recoverable value.

At Ferrovial Services we have spent years preparing ourselves for this transition from Linear Economy to Circular Economy and have now assimilated this work philosophy as a tool and an objective, looking at waste as a raw material from which we need to extract all its value.

Today, our first major projects in this area are beginning to see the light of day, strengthening our ability to develop complex and higher added value projects for our customers, and reinforcing our commitment to sustainable development and to adopting management models based on the principles of the circular economy. We are currently working on two lines of business.

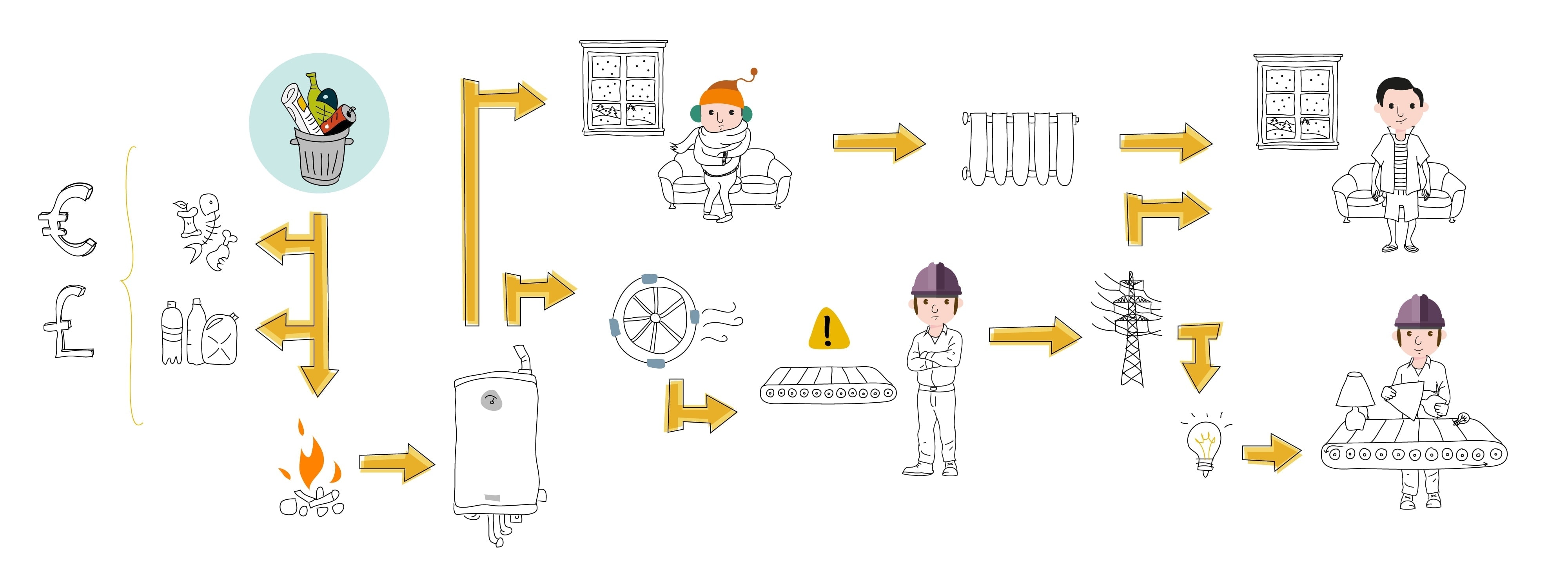

The first line of business is the direct combustion of waste in a furnace to produce high-pressure steam in a boiler. The steam can then be used directly as a heat source for home heating or in industrial processes, although it is more commonly used to power a turbine and generate electricity that is directly exportable to the electricity distribution grid.

Ferrovial Services is building its first large-scale power generation project for the Council of North Yorkshire in Northern England, with a capacity to process 320,000 tons of waste a year and generate more than 200,000 MWh of electric power a year (enough to meet all the electricity needs of 40,000 households). Also, Ferrovial Services is now developing other distinctive power generation projects that go one step further in technology.

At the moment Ferrovial Services is completing the construction of the waste gasification facility in Milton Keynes on the outskirts of London, which is scheduled to begin to operate in February next year, and is also preparing to take on the construction of a second gasification facility on the Isle of Wight. Compared with direct incineration of waste, gasification opens up a range of possibilities by obtaining a gas rich in carbon monoxide and hydrogen which can be recovered either via combustion in steam boilers or more power-efficient engines or be used directly to generate raw materials for the chemical industry, thereby creating added value from the waste.

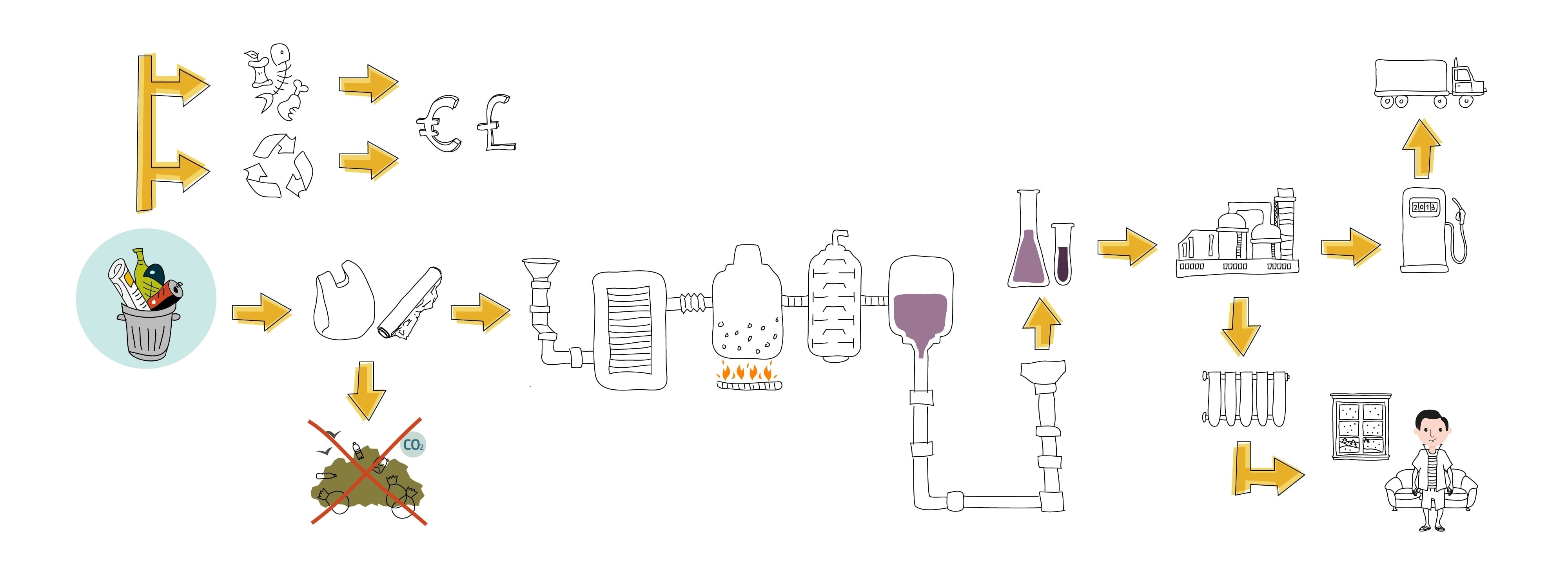

The second line of business consists in TRANSFORMING RUBBISH INTO FUEL. We are developing a project in the Ecopark in Toledo to transform plastic into a liquid fuel, which is yet another tangible and close-at-hand example of Ferrovial Services’ ability to be one step ahead of traditional technologies.

We first convert the waste into a solid fuel called Refuse Derived Fuel or RDF. Here is where Ferrovial Services’ experience in designing RDF production plants offers added value and allows us to expand the value chain and deal with the complexity of these projects with confidence in our knowledge of the technological challenges posed by these facilities.

It is a flagship innovative project that will allow recovering 9,800 tons of urban waste plastic a year, thus avoiding the dumping of plastic in landfills, and obtain roughly 600 litres/hour of a liquid fuel that is similar to diesel C.

The transformation is carried out using a method called flash pyrolysis, which is based on the thermal decomposition of the organic material in the absence of oxygen, at high temperatures and in the presence of a catalyst, taking only a fraction of a minute (seconds).

In short, the production of this liquid is a step further for Ferrovial Services and means that it is prepared for the eco-fuel revolution. The added value of this product is that it is easily transportable and can be used as a fuel in all types of diesel engines, we therefore transform waste into a storable and transportable commodity that is more versatile than refuse-derived solid fuel.

There are no comments yet