Since the construction of the first offshore wind farm (i.e. a wind farm in the sea at some distance from the coast) off the coast of Denmark in 1991, the offshore wind energy sector has grown enormously – driven mainly by northern European countries, and particularly the UK, Germany and Denmark – to become an important source of energy in today’s world, with undeniable potential for the future.

Up until the first half of 2015, 3,072 turbines had been connected to the European network, totalling 10.4 GW of installed capacity, thanks to the construction of 82 wind farms in 11 countries. A further 15 wind farms are currently being built, which will add 1.9 GW to the network. Although various factors have reduced the projected 40 GW of capacity which was to have been installed by 2020, annual investment in the sector, estimated at over 10 billion euros, nevertheless represents a volume such that it has become a strategic and priority business for large European companies, Ferrovial-Agroman amongst them.

To achieve the targets set by the industry, European ports have a critical role to play within the supply chain. Depending on the installation strategy adopted, the port may be used as a base for assembly, handling and/or manufacture, but it will in all cases act as the supply chain hub, through which all components, structures and turbines making up the wind farm must pass. This means that the first step in the construction of a wind farm must be the selection of one or more base ports and, if necessary, the adaptation thereof as per the requirements of each particular project.

Over the life cycle of a wind farm project, the phases of manufacture, preinstallation, installation, commissioning, operation and maintenance, and eventually decommissioning, will in all cases require one or several port terminals with specific facilities for the different construction phases. The main companies in the supply chain will set up an operating base in the port, and the port terminal will thus become a hub for first tier logistics, and as such a key factor in the smooth running of the project.

The port is therefore of critical strategic value for all stakeholders.

The installation strategy used by the project developer will have a direct impact on the properties and facilities that manufacture and assembly port terminals must have, as well as on the type of port to be used. There are currently two different approaches based on the number and types of installation and transport vessels, and the level of assembly to be carried out in the port.

- Transiting strategy: Transport of components to the wind farm in installation vessels. Depending on the operations carried out in the port terminal, two methods of construction can be further differentiated: if manufacture and assembly of components is carried out in the port, or only preassembly thereof.

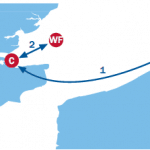

- Feeding approach: Components are transported to the wind farm in transport or feeder vessels.Today, the most widely used strategy is transporting components which have been preassembled in the port.

- Transiting. Manufacture and preassembly in port. Source: EWEA, BVG Associates

- Transiting. Preassembly in port. Source: EWEA, BVG Associates

- Feeding. Offshore assembly. Source: EWEA, BVG Associates

The type of port terminal to be used by the offshore wind sector depends, first and foremost, on the phase of the project for which they will be used: whether for the installation phase, or for operation and maintenance of the wind farm.

Ports used during preinstallation and installation of a wind farm must have major components and facilities, and depending on the installation strategy to be used, can be of the following types:

- Import/export ports: Ports receiving components from onshore manufacturers. Components are handled and stored for subsequent loading onto vessels which will transport them to manufacturing and assembly ports.

- Manufacturing ports: Due to the ever larger size and weight of wind turbine components, road transportation is becoming less viable, and turbine and foundation manufacturers are increasingly establishing manufacturing facilities in suitable ports. This follows the example of cable manufacturers, where production at ports has been well established since the beginning of the offshore cable industry.

- Assembly ports: Preassembly of components received from manufacturing plants takes place here. Components are received either by road transport or, increasingly, by sea.

The use of the same port terminal for manufacturing and assembling wind turbines and nacelles will depend on the savings to be made by the project through optimisation of the supply chain.

- Mobilising port: These are ports receiving turbine components and foundation units which have already been preassembled to a degree that allows them to be loaded onto vessels for transport to the offshore wind farm where they will be installed. No manufacturing, assembly or storage takes place; they are simply ports which provide support for construction of the farms.

- Offshore ports: This is a new concept which is still at study stage. These ports would be multipurpose offshore terminals, allowing a reduction in installation and transport costs, as well as a drop in response times for wind farm maintenance.

The type of port used will depend on the installation strategy adopted, a cost analysis, the distance from the manufacturing centres to the wind farm, the distance from the coast to the wind farm, and future developments in the area.

After commissioning of the wind farm, an operating base within a port is also required, but with different and less exacting requirements:

- Operation and maintenance ports: These ports provide the wind farm with support services for operation and maintenance. They must support a rapid response for contingencies in operation, and so must be located at a relatively short distance from the farm to reduce travel times for staff and parts, and optimise offshore on-site working times. These ports require no large-scale installations or specific properties.

The port is of critical strategic value for all stakeholders, and thus selection of the most appropriate port is key to the smooth running of the wind project.

3 comments

sdlc corp

31 of January of 2023

I read your complete blog and you delivered the best information about How Blockchain is transforming supply chain?. I am also sharing information related to new technology such as Blockchain, NFT Marketplace Development, and Metaverse. Visit@: https://sdlccorp.com/nft-marketplace-development/

blockchainx tech

30 of July of 2024

we specializes in creating and implementingblockchain development solutions tailored to meet various industry needs.

Ethan Smith

20 of August of 2024

Softlabs Group offers blockchain services like developing apps, smart contracts, and cryptocurrencies, making it easier for businesses to use blockchain technology effectively. https://www.softlabsgroup.com/blockchain-development