The aviation industry emitted 915 million tons of CO2 in 2019, 2% of all CO2 produced by humankind that year. Over the next few years, ATAG (Air Transport Action Group) has set the goal of reducing CO2 emissions by 50% from 2005 levels by 2050.

Following the signing of the Paris Agreement, air transportation was the first sector to commit to fighting climate change. However, continuous improvement in aircraft efficiency hasn’t been enough in recent decades due to the growth seen year after year. As a result, innovative solutions that radically reduce aviation’s climate impact are needed.

Using hydrogen as a jet fuel offers the possibility of completely eliminating CO2 emissions during flight. Thus, this promising energy vector has been presented as one of the leading alternatives to replace traditional aviation kerosene, along with electric motors powered by batteries and sustainable aviation fuels.

Different types of hydrogen propulsion

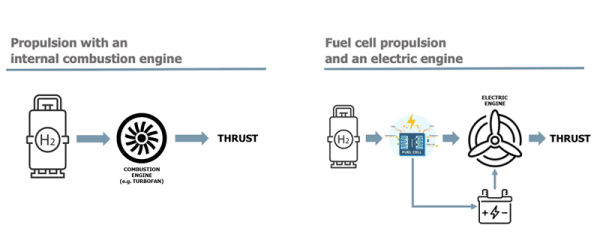

There are currently two hydrogen propulsion models for airplanes: the first entails using hydrogen to produce electrical energy through fuel cells, powering an electric motor. The second propulsion model is based on direct hydrogen combustion in internal combustion engines, similar to those used in airplanes today.

Source: Ferrovial Airports

Source: Ferrovial Airports

Both solutions are in development, and the main advantage they offer is totally eliminating CO2 emissions during flight. But they have their own pros and cons: direct hydrogen combustion entails emitting NOx and water vapor, while fuel cells are more efficient and only have water vapor as a by-product.

It is estimated that using hydrogen as a fuel could reduce the climate impact during flight by 50 to 75% with hydrogen turbines and 75% to 90% using hydrogen cells.

Due to the need for batteries and the current level of tech development, using hydrogen fuel cells is limited to regional aircraft and short-range flights. Implementing hydrogen combustion engines would enable replacing kerosene in mid-sized and large aircraft for flights of up to 10,000 km.

Hydrogen: propulsion with great potential but many challenges to address

In addition to not emitting CO2 during flight, hydrogen is the most abundant element on our planet, making it unique among other sustainable sources for propulsion.

However, production, storage, and distribution needs keep hydrogen from being widely implemented in airplanes.

During hydrogen production, large amounts of energy are consumed, and this must come from renewable sources so that hydrogen can be used as a sustainable fuel. To meet aircraft propulsion’s high demand for hydrogen, production of blue and green types of this element – those considered environmentally friendly – will have to increase significantly.

On the other hand, the tanks needed to store the hydrogen used to power an aircraft are quite large. If we also consider that hydrogen is often used in a liquid state to reduce its volume, these tanks must be pressurized and withstand very low temperatures. Thus, much thicker tanks will be needed, meaning more weight.

Consequences of bringing hydrogen onboard airplanes

Some 72% of CO2 emissions from aviation are produced by mid-sized and large aircraft, those most used in commercial aviation. Furthermore, flying at high altitudes means those emissions have a greater impact on the environment. Implementing hydrogen propulsion via internal combustion engines or hybrid fuel cell systems with internal combustion engines on these aircraft would mean lowering most of the emissions.

Replacing kerosene with liquid hydrogen means increasing the volume of current aircraft fuel tanks by a factor of four and reducing the weight of fuel by 70% to fly the same distances.

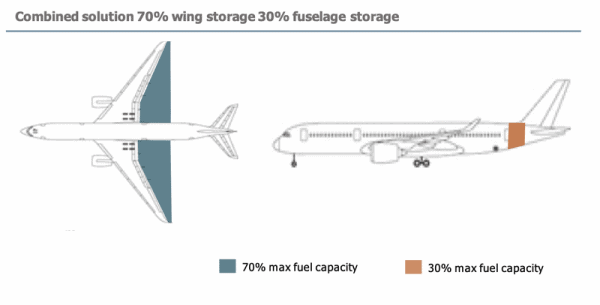

Due to the size of tanks needed to store the hydrogen consumed by aircraft on long-range flights, aircraft design will have to be modified. Current alternatives involve increasing the wings’ volume to increase storage capacity there and/or increasing the length of the fuselage to add additional tanks.

To achieve the current maximum range of an aircraft like the A350, multiplying the wing area by 2.5 and an additional tank would be needed, occupying 5% of the fuselage length in a combined solution.

Source: Ferrovial Airports

Source: Ferrovial Airports

As for the aircraft’s weight, this design change would mean reducing the final take-off weight by up to 11%, compared to the maximum take-off weight.

Implementing hydrogen as a fuel for internal combustion engines would therefore not only reduce CO2 emissions; it would also offer the opportunity to increase payload.

Hydrogen vs. Other propulsion alternatives

Besides hydrogen, the aviation industry is committing to developing 100% electric airplanes and using SAFs (Sustainable Aviation Fuels).

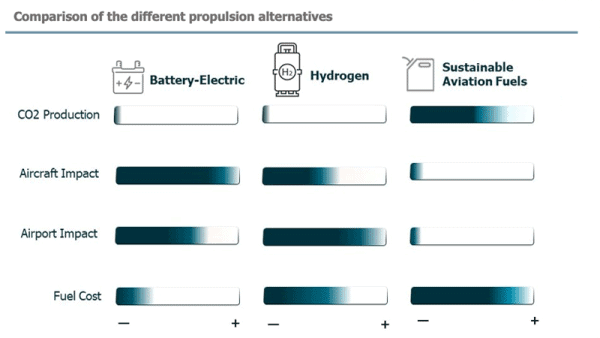

SAFs are currently used with kerosene at levels up to 50%, but they’re predicted to reach 100%. They can be used in any type of aircraft and without any range limitations. The high cost and partial reduction of CO2 emissions during flight make this a good alternative for the immediate future, but it is not a definitive solution.

Aircraft equipped with fuel cells and electric motors will make zero-emission flights possible. However, application is limited to small aircraft and flights less than 1000 km, pending further technological development on the batteries needed.

Comparing the three sources of propulsion based on the impact their implementation at airports and in aircraft would have, hydrogen and electric propulsion would require more investment. This is because new distribution and storage networks would be required at airports, along with new aircraft designs. SAFs, on the other hand, don’t require any major changes since they use the same systems as kerosene.

Source: Ferrovial Airports

Source: Ferrovial Airports

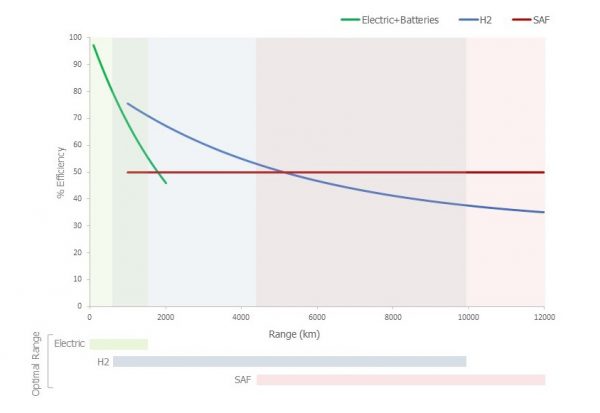

Considering the lower environmental impact of the various alternatives and the costs associated with implementing them, each has optimal distance ranges. By combining the different alternatives and implementing them on flights where they are most efficient, we could achieve maximum reduction in emissions. Still, large investments would be needed to develop these three alternatives. Besides, this all depends on the technological advancements made for these propulsion systems and the development of future alternatives, such as the CO2 propulsion proposed by Oxford University.

Note: Efficiency is the combination of the total cost and the power obtained as compared to traditional fuel (100%)

Note: Efficiency is the combination of the total cost and the power obtained as compared to traditional fuel (100%)

Source: Ferrovial Airports

Based on the characteristics of these current alternatives, we can conclude that the versatility of hydrogen propulsion enables it to cover a wide range of aircraft and flight distances. As such, committing to hydrogen-powered aircraft will achieve the greatest possible environmental benefit, reducing CO2 emissions from aviation by up to 89%.

There are no comments yet