Inside the ecosystem of engineering and construction, robots are positioning themselves as highly effective tools in complex environments. Their versatility, combined with their performance, makes them a valuable investment for many organizations looking to improve their production processes.

Although they are not exactly low-cost, their ability to free technicians from repetitive, routine tasks allows them to focus on tasks of greater complexity and responsibility, which means increased efficiency and productivity for the company. In addition, they can be programmed to perform specific tasks with a precision and speed that sometimes exceed human capabilities. That is why they are slowly becoming an essential tool for projects, making it possible to improve processes and increase competitiveness in an increasingly demanding market.

How can robots help the construction sector?

When equipped with different sets of sensors and cameras, robots often perform automated tasks, such as taking measurements or pictures, making videos, seeing outside the visible (human) spectrum, or detecting risk points. For example, a CO₂ sensor would help locate leaks in industrial plants since the concentration usually occurs near the breakage.

These robots can also be used as remote-controlled, unmanned drones so that technicians can expand their human capabilities. For example, it is possible to move material with robots, access unsafe places, and even do small remote jobs (such as measuring high temperatures).

The digitalization and implementation of robotic solutions can accelerate automation in the construction industry, which in turn brings a number of benefits to the sector:

- Boosting the productivity and efficiency of tasks;

- Reducing operational costs and losses;

- Increasing health and safety at work (“people care,” technologies to relieve workers, such as handling heavy loads, avoiding strenuous postures, attenuating mechanical vibrations…);

- Simplifying processes;

- Automation to facilitate management tasks.

What is ‘staking,’ and what does it entail in construction projects?

In this context, one task where robots can perform with high precision and performance is staking. This activity is essential to ensure the proper execution of construction since it consists of marking the ground with the positions of all the elements that will be built on the site according to the plans.

In construction, the most typical cases are:

- Staking for land divisions or plots

- Staking for excavation or emptying land for future construction

- Staking axes, structures, or services in civil works

- Interior staking of works (partitions, installations, stairs…)

- Staking supply lines in housing developments (power lines, drainage networks…)

During traditional staking, surveyors and site managers use a variety of tools, including alignment cords, bubble levels, water levels, topographic (laser) levels, tachometers, squares, tape measure, topographic GPS, and much more.

In all these cases, it is important to perform proper staking to avoid errors in the site execution and thus guarantee its success.

What are staking robots?

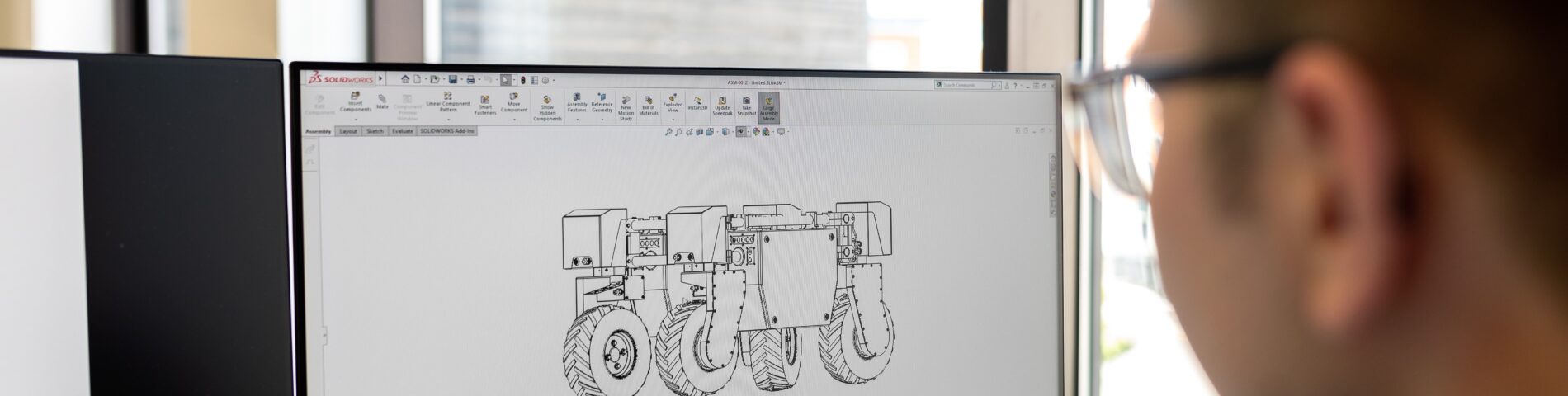

Staking robots are semi-autonomous programmable machines for capturing or marking up data in a staking scenario. They assist the construction staff and are able to perform some of the classic staking functions, but always as a support to expert staff.

These robots work on the ground and are currently geolocated using total station or GPS. Through the application and through a device like a tablet or mobile, they can read and reproduce information from a 2D blueprint or a 3D model on the ground. They literally “get the blueprint on the ground.”

There are different options within staking robots according to the type of project. For example, the specific robots for civil works and, therefore, for rougher terrain have more robust designs, with wheels that are larger in diameter and thicker. This type of staking robot has lower accuracy (about 2cm line width) and can print dots and lines on the ground for surveying work.

On the other hand, the more specific staking robots for building or interior works are usually smaller and more limited by the terrain condition, mainly working on slabs or very compacted, obstacle-free terrain. This allows them to achieve accuracies of up to 2mm so that they can print all kinds of lines, text, and even QR codes with all the information about the blueprint that may be useful later for carrying out the elements laid out.

Advantages of using staking robots

The use of robots in this task can significantly improve the efficiency and accuracy of the process, which translates into savings in time and resources. These robots enable the construction site personnel responsible for these tasks to engage in other activities that require more specific experience and knowledge, as well as automating mechanical activities, such as marking axes or control points, measuring distances, noting heights, or checking unevenness. These are indispensable aspects of construction, but they take up a lot of time and don’t require advanced skills.

It is worth noting the improvement in the precision of the staking offered by the robots, ensuring a complete match with the design from the blueprints and 3D models of the project. This is especially visible in building projects with a high degree of complexity.

In addition, the use of these robots offers improved health and safety for workers since it reduces possible injuries and allows safe access to areas with specific risks associated with the project.

Robots will not replace humans

Lately, between the very rapid advances of robotics and the impressive progress of artificial intelligence, the future of science fiction movies seems more and more realistic and achievable. However, many solutions are not yet economically viable, especially for such a competitive sector as construction.

The reality is that very advanced, “futuristic” robots are not necessary to have an impact in the sector; there are more accessible – and more affordable – solutions. One significant change can be achieved in the way of approaching work with existing robots (laser scanner, LiDAR, staking robots, drones, mobile mapping …) loaded with sensors, cameras, and beacons. It is important to remember that they lack any kind of creative ability or decision-making. A staking robot can set up relatively reliable plans (they usually need human retouching), with the bonus of making recordings associated with geopositioning data on those plans, but it cannot understand these plans nor choose between one development or another. That’s what people are for.

The power of this robotic force is relieving working hours. If traditional staking requires a full working day, with these small assistants, it is possible to cut that time to a few hours, using humans for tasks where we are intrinsically needed.

In the Industry 5.0 sector, robots have made a grand entrance onto construction sites, and they are already providing support for teams at the construction site, which allows them to optimize and maximize resources, as well as protect their health without replacing them. In addition, in the current context of a lack of qualified workforce, it is important to allow our top professionals to use their time in the best possible way.

There are no comments yet