Whenever we talk about BIM, we encounter a whole set of phrases that we’ve heard countless times. Sometimes, though, neither the speaker nor the listener is really clear on its meaning: “BIM is a new methodology,” “BIM is based on three pillars: processes/procedures, people, and tools,” or “The important thing about BIM is data.”

Despite the questions that come up, people repeat these phrases over and over at different exhibitions and courses. By the end of it, listeners will often recall 3D images of construction projects that seem finished before ground has even been broken. And let’s face it, it’s really cool to see 3D models. Sometimes, they can almost be hypnotizing. Building, coordinating, planning, the unexpected surprises, changes, modifications… You can bypass all that and see the final result. You can even walk around inside a future building or infrastructure before construction takes place. Some call it Hollywood BIM, for obvious reasons…

Given these situations, this article humbly attempts to explain these concepts once again: “BIM is a new methodology,” “BIM is based on three pillars: processes/procedures, people, and tools,” and “The important thing about BIM is data.” This time, though, we hope to shed a little more light on the subject, as well as the goal of helping non-BIM readers understand it with an example applied to a project in Chile.

Applications in construction projects

In Chile’s construction sector, it is the norm to prepare reports for clients that look at a project’s progress, quality review, environmental measures, prevention indexes, compliance with planning, the administrative situation, and so on. These reports and monitoring require the team’s time and dedication. There are also the internal reports that every construction company prepares for monitoring and analyzing its projects, so proper monitoring involves using resources. That entails paperwork spanning departments and people. Each individual handles these papers in their own way, and they may not start or end up in the same place. Seeing how things currently work, it makes sense to rethink how we’ll move forward. Hence the concept of a new methodology. Its objective should be none other than to have a common, reliable source of information for everyone involved in construction. Our colleague Teo will be beside himself with excitement if we finally achieve this…

Our experience with projects in Chile

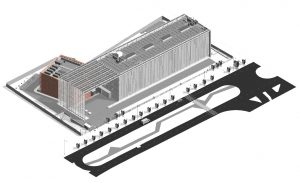

We’re currently participating in work on the new headquarters for the Coordinador Eléctrico Nacional, the national electric coordinator. The complex is made up of two buildings: an office building for all administrative tasks, and a DataCenter and Control Room where all electrical transmissions in Chile will be directed. The latter must never fail, so it is classified as TIER III. For those who don’t know, this classification certifies that whatever happens, its operability is ensured 99.982% of the time annually. It is therefore designed like a bunker, resting on seismic isolators. Let’s not forget that it is being built in Chile, the most earthquake-prone country in the world: about 1/3 of the world’s seismic energy is released in Chile. But that’s a different story.

Going back to construction, BIM is a trending topic, and as such, Chile’s Coordinador Eléctrico Nacional requested meeting some requirements through this methodology. In short, these translate into the following uses: generating as-built documentation, monitoring the progress of execution (programming), and developing 3D models that will allow the building to be operated and maintained in the future. At Ferrovial, we firmly believe in BIM methodology. We decided to incorporate more uses that would add value for both the client and us. The following stand out among these: generating digital information directly in the field, obtaining measurements, detecting conflicts and preparing constructive reviews, integrating subcontractors, and monitoring quality control. To do this, we rely on the Department of Digital Construction and Data Management’s experience, and we’re utilizing the BIM standard developed by PlanBIM Chile as a reference point.

Generally, when talking about BIM, very few people stress quality. Nobody makes presentations about quality. It isn’t flashy or eye-catching; it doesn’t sell. This is the area where data management is of great importance for us, and implementing it comes in handy to clarify the questions raised at the start.

How is BIM implementation done?

To carry out implementation, the head of BIM for construction in Chile, Pablo Galiana, met with the project’s Group Leader, Nuria Venero, and those in charge of quality nationally, Seida González, and specifically for this project, Andrés Carrillo. They analyzed how to proceed to ensure quality in construction at Ferrovial, as well as the possibilities of simplifying it and making it more productive. For quality, the norm is preparing procedures on paper signed (after everything is verified) by the head of the construction company, the head of the project’s technical inspection, and sometimes the client’s lead contact. Like all papers, these documents are usually stored so well somewhere so that when you need them in a few years, you’re never able to find them. But with the advent of digitization, now they’re scanned when construction finishes. Months scanning papers and archiving them digitally… We’ve already gone digital!

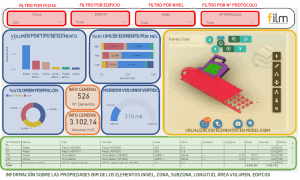

But back to the point. Once the situation had been analyzed and the starting point established, the team in question decided that the protocols would be generated digitally and signed directly on-site on a smartphone or tablet when everything checks out as having been carried out properly. This way, it is archived and saved digitally straight away. In addition, they agreed to associate each protocol with the corresponding constructive element, establishing a relationship between the data generated in the field and the geometric data of the model’s elements. On the one hand, we obtain information on whether a construction element meets quality requirements, when monitoring was carried out, signatures of those in charge… On the other, information like volumes, surfaces, areas, characteristics, manufacturers, and so on is also obtained. By crosschecking this information, we can monitor progress in real-time, signed off by the relevant heads certifying it. Most importantly, we gain a highly useful source of information for everyone involved in the project: measurements, monthly progress percentages… I think that this sheds some light on the fact that “The important thing about BIM is the data,” as well as one of the three pillars: processes/procedures.

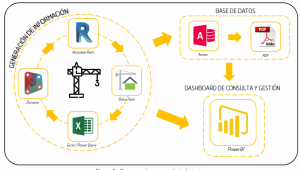

Once the goals and how they were to be addressed had been established, we went on to study the tools. Based on a comparative analysis of the functionalities of some of the most powerful tools on the market, we chose the one best suited to the people and processes to be carried out. In this case, the models were developed in Autodesk Revit, and Dalux Field was chosen for snagging and consulting both the Ferrovial team and subcontractors, inspection, and the customer. Managers, surveyors, supervisors, production managers, site managers, installation technicians, quality managers… They simply have to use a phone or tablet to see the model on-site and review the quality with the technical inspection since Dalux Field makes all project information accessible. But since this is a prepaid online platform, all of the information is periodically exported to an Access database, which we already own and is hosted by the well-known Office 365. Thus, we kill two birds with one stone and address the two remaining pillars: tools and people.

What platforms did we use?

Those of you who have made it this far are probably wondering whether learning to use the Dalux platform, Revit, or Access is necessary for participating in this process. The answer is no. This project team integrated everything into a simple, intuitive viewer using PowerBI. For those who aren’t familiar with it, PowerBI is a Microsoft tool that lets you generate interactive Dashboards that are quite easy to use. The best part is that the dashboard enables any BIM layman to check the amount of concrete, reinforcement, or any element needed on any date; group or ungroup queries; check quality certificates for different elements, and see everything in a 3D rendering. All in an interactive, visual, intuitive way with no specific knowledge of Revit, Dalux, or Access.

It looks like we are definitely starting to make the switch from piles of paper to envisioning a new era of digital control. The foundations are being laid for a new period where the quality manager doesn’t have to waste time on paperwork, instead checking that quality really is achieved. A new era where the Group Leader has access to information on progress in real-time and can review shipments that have been made, planning… all directly and easily. A new era of collaborative work where implementing BIM really does reduce the workload and help focus on what is important while also being more productive.

I hope that those of you who’ve taken the time to read about our experience better understand those three phrases we’ve all heard so many times. Above all, I hope you can see the infinite possibilities offered by this way of working.

There are no comments yet